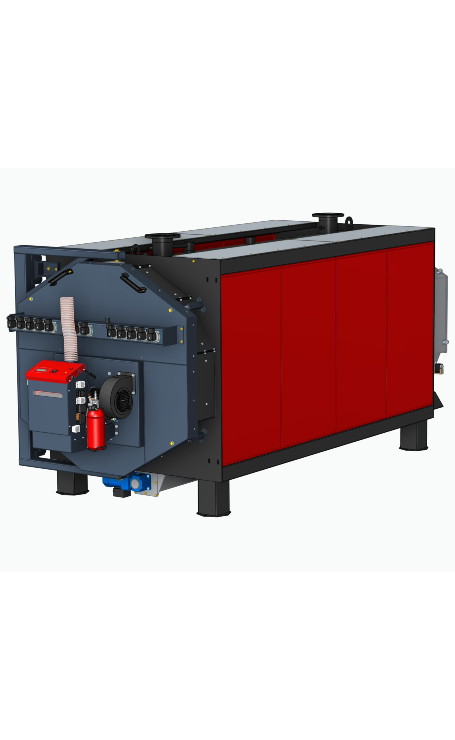

PELLTECH EVERCLEAN PK1000

PELLTECH EVERCLEAN PK1000

Industrial pellet boilers with 6 different cleaning mechanisms! This highly efficient 3-pa…

Industrial pellet boilers with 6 different cleaning mechanisms!

This highly efficient 3-pass boiler is specially designed for pellet burners. The 6 separate cleaning mechanisms guarantee long maintenance intervals. The boiler is equipped with a pneumatic cleaning system for the third pass heat exchanger tubes. The flying ash will be directed to back of the boiler and then moved to the ash container. Automatic ash removal of the boiler also consists the scrape on the bottom of the boiler, which delivers ash to a suitable container behind the boiler or outside the boiler house. To ensure the cleanest flue gases there is an ash cyclone with automatic ash removal connected to the boiler, which will catch all the fine particles.

All boilers are remotely controllable. Every second even the smallest details about boilers work are logged and visible in special website or App. This incredibly precise monitoring makes technicians work so much easier when some failures should occur and gives a chance to analyze the burning process for better adjusting of the burner parameters.

Well-thought-out construction of the boiler door allows very easy accessibility to the boiler inside. Thanks to its compact size it can be installed into sea containers or any similar space–saving buildings.

Pelltech produces pellet boilers from 15kW to 1 MW and pellet burners from 20 kW up to 1,5MW. If there is an industrial process converted to pellets and only burner is needed (for example drying, evaporating) then our fully-automatic and reliable pellet burners are perfect solution. We help you with a professional equipment and professional advice.